ASR 3015 PR

mere

EML-AJ kombinationsmaskinen sammenbringer AMADA’s patenterede dobbelte servomotor og en fiberoptisk laser med hurtigt integreret hybriddrev på en enestående og perfekt måde. Designet til at minimere manuelle operationer, gør den ideel til komplet bearbejdning.

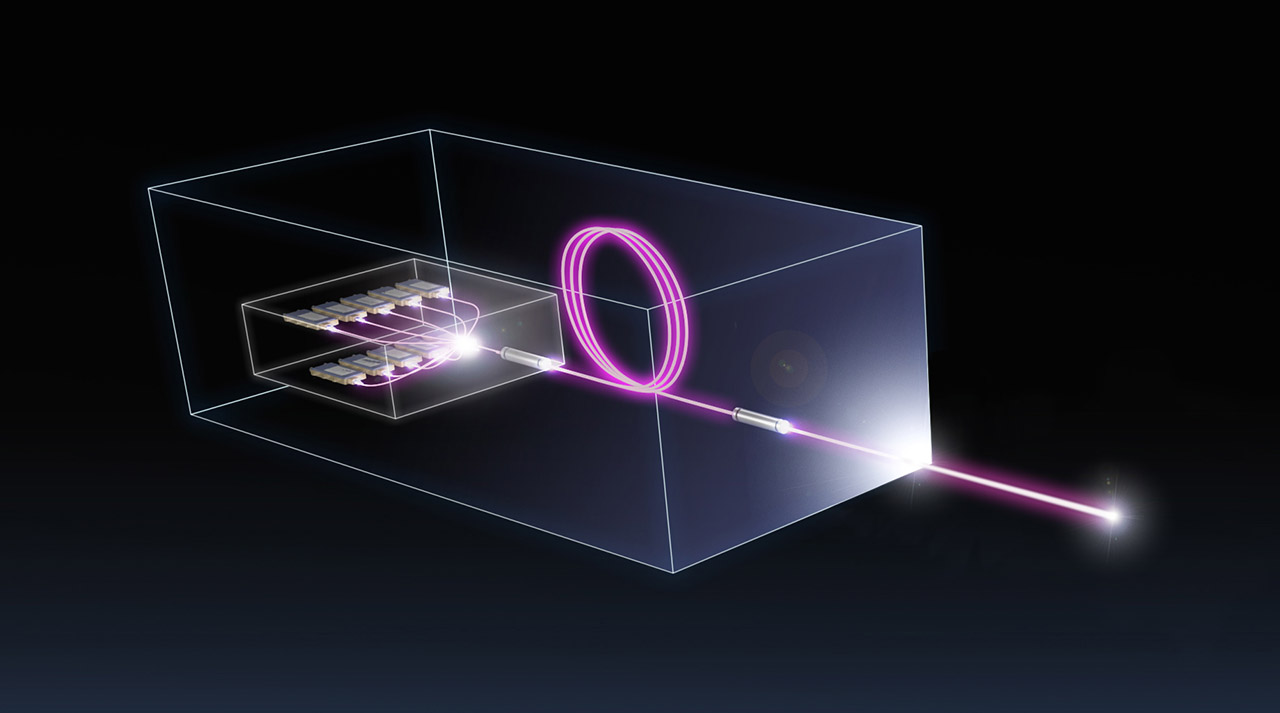

ENKELT MODUL FIBERLASERKILDE: Ved hjælp af et enkelt 3 kW diodemodul og uden brug af conbiner, er kvaliteten af laserstrålen der genereres af EML-AJ meget høj.

MULTI-TOUCH NUMERISK STYRING: EML-AJ er udstyret med den nye generation AMNC 3i numerisk styring. Det 21,5 tommer store multi-touch LCD panel med sin brugervenlige overflade er enkel og intuitiv.

MULTIFUNKTIONEL REVOLVER: EML-AJ er udstyret med en multifunktionel revolver, der også indeholder 4 dedikerede gevindstationer for M2.5 til M8 tappe. Hvis gevindskæring ikke er påkrævet kan disse 4 stationer anvendes til standard B-station stanseværktøjer.

| EML-2515AJ | EMLZ-2515AJP | |

|---|---|---|

| Press capacity (kN) | 300 | 300 |

| Laser power (W) | 3000 | 3000 |

| Machine frame | Bridge frame | Bridge frame |

| Punching accuracy (mm) | ± 0.1 | ± 0.1 |

| Number of stations | 44 | 44 |

| Tool turret type | Z-Turret | Z-Turret |

| Table loading weight (kg) | 220 | 220 |

| Table drive | AC Servo drives | AC Servo drives |

Simultaneous axis speed: | ||

| Punching X/Y (m/min) | 128 | 128 |

| Laser X/Y (m/min) | 141 | 141 |

Dimensions: | ||

| Length (mm) | 5689 | 6808 |

| Width (mm) | 6927 | 6927 |

| Height (mm) | 2525 | 3010 |

| Weight (kg) | 24000 | 27500 |

PDC (Automatic Punch / Die Changer)

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.

Laser class 1 when operated in accordance to EN 60825-1